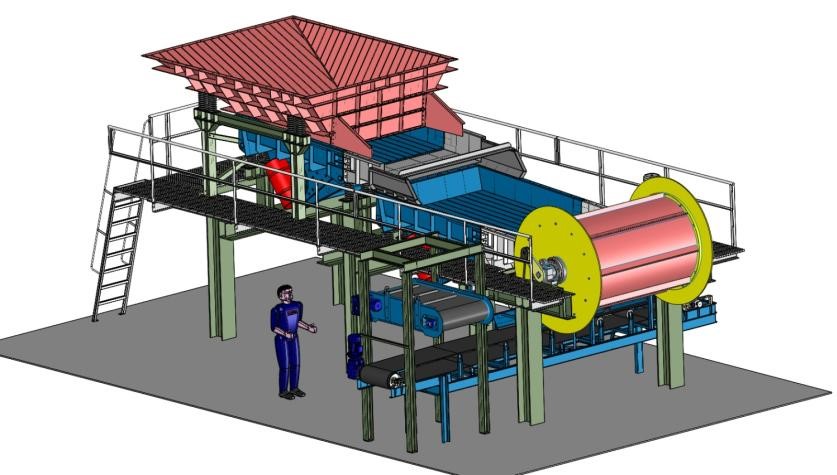

Scrap cleaning

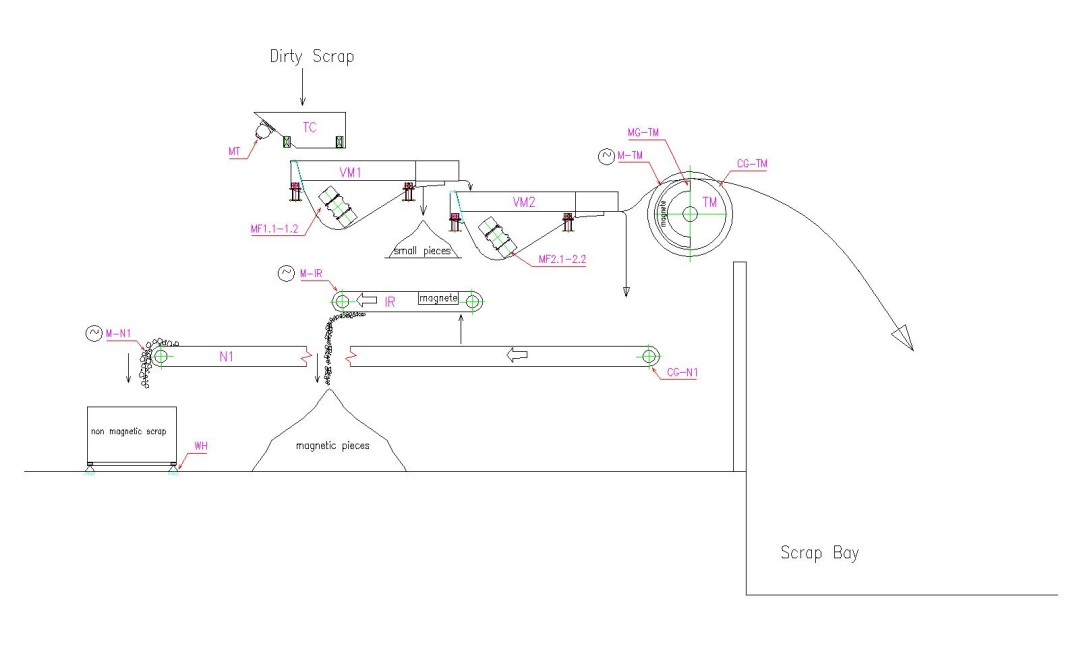

The system separates non-magnetic and inert materials from magnetic scrap.

system separates non-magnetic and inert materials from magnetic scrap.

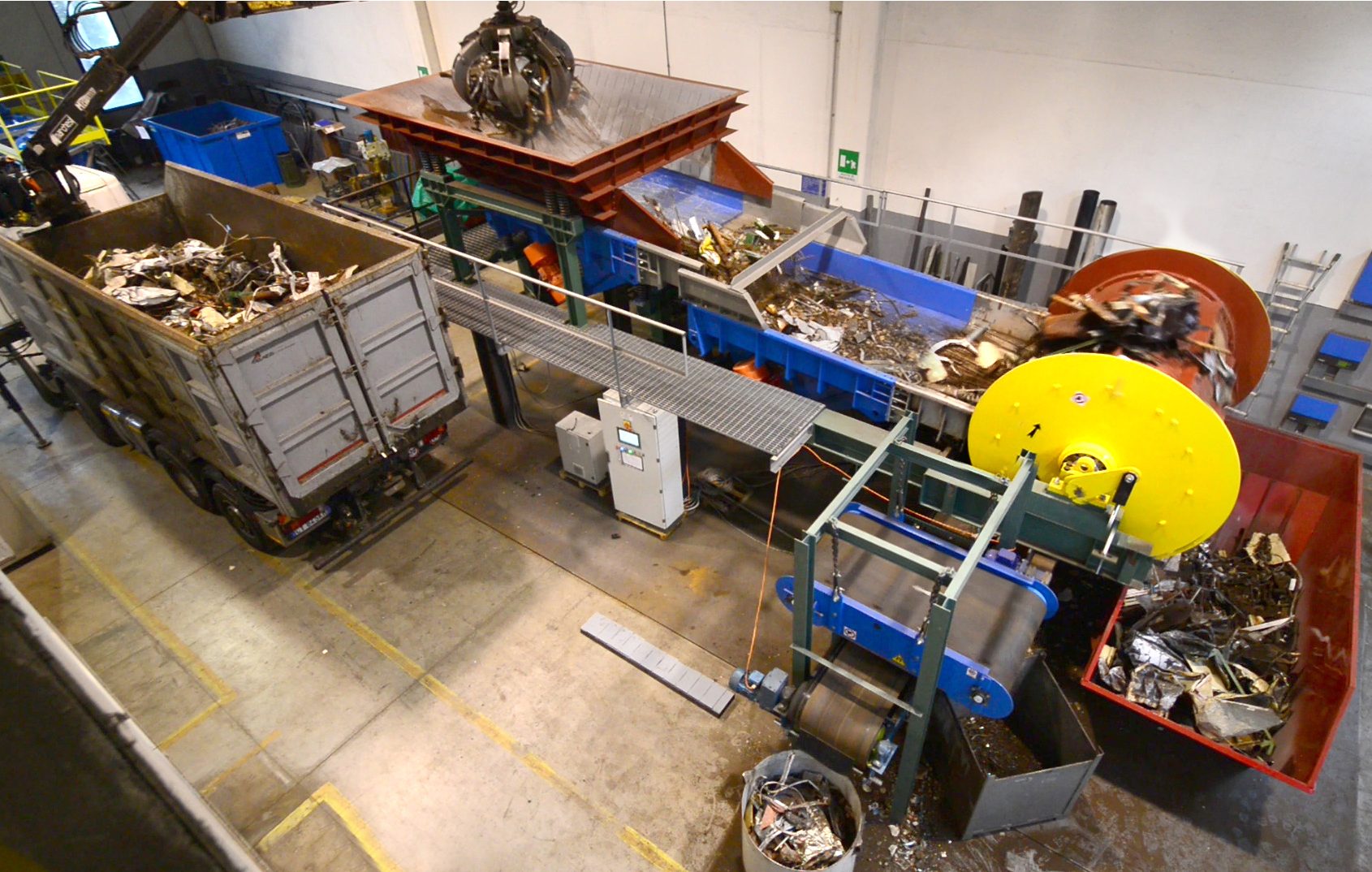

The main separation is carried out by means of a magnetic drum that picks up the scrap at the discharge of a vibrating table and discharges it into the main scrap pit.

The secondary iron separator recovers small magnetic scrap from the evacuation belt of non-magnetic materials.

system separates non-magnetic and inert materials from magnetic scrap.

system separates non-magnetic and inert materials from magnetic scrap.The main separation is carried out by means of a magnetic drum that picks up the scrap at the discharge of a vibrating table and discharges it into the main scrap pit.

The secondary iron separator recovers small magnetic scrap from the evacuation belt of non-magnetic materials.

Insieme del sistema in fase di test con rottami